In-Mold Decorations Demystified: Opening the Tricks Behind This Advanced Manufacturing Process

In today's hectic manufacturing landscape, in-mold designs have actually emerged as an innovative strategy that continues to intrigue sector professionals. This cutting-edge manufacturing procedure holds the promise of transforming the method we view and use attractive elements in various items. As we delve into the ins and outs of in-mold designs, a world of cutting-edge opportunities unravels, providing a glimpse into a world where design fulfills performance in a smooth fusion. In-Mold Decorations. Stay tuned as we study the underlying principles and reveal the enigmatic attraction of in-mold decors, clarifying the secrets that push this process to the forefront of contemporary manufacturing methods.

The Advancement of In-Mold Decorations

The advancement of in-mold designs has been marked by considerable advancements in technology and style advancement. Originally, in-mold designs were restricted in their intricacy and shade choices. However, with the introduction of new production strategies and materials, the possibilities have expanded greatly.

One key innovation has been the advancement of high-resolution printing procedures that allow for detailed styles with vibrant colors to be transferred onto items throughout the molding process. This has made it possible for suppliers to attain photorealistic photos and thorough graphics that were formerly unattainable.

Moreover, the integration of robotics and automation in the in-mold design procedure has improved efficiency and consistency in applying decorations to products. This not just minimizes production time but also enhances the total high quality of the ended up products.

Recognizing the In-Mold Refine

Marked by significant developments in technology and layout innovation, the advancement of in-mold decors has led the way for a deeper understanding of the elaborate procedure associated with developing these decorative elements. The in-mold process is an advanced manufacturing strategy where ornamental components are incorporated straight right into the end product throughout the molding procedure. This method entails positioning a pre-designed decoration, such as a visuals or label, into the mold tooth cavity prior to infusing the product. As the product flows right into the mold and mildew, it bonds with the decoration, causing a smooth assimilation of the design right into the product.

Comprehending the in-mold procedure calls for exact control over different criteria, including timing, temperature, and stress, to make sure the decoration adheres appropriately to the product. Furthermore, selecting the right products is critical to attaining premium results. By grasping the details of the in-mold procedure, makers can generate visually striking items with durable, durable decors that boost both the aesthetics and performance of the final item.

Advantages of In-Mold Decorations

Advancing product visual appeals and sturdiness, in-mold decorations offer a structured strategy to integrating decorative elements throughout the manufacturing process. One of the crucial benefits of in-mold decors is the smooth assimilation of textures, shades, and graphics directly right into the product throughout the molding procedure. In-Mold Decorations. This removes the demand for post-production design approaches, such as painting or printing, which can be expensive and taxing

Furthermore, in-mold decorations are extremely durable as the graphics are encapsulated within the original site product, making them immune to put on, scratches, and fading. This causes products that keep their aesthetic charm and branding for a longer duration, even in harsh environments.

Along with improving looks and durability, in-mold decors likewise supply boosted style flexibility. Manufacturers can easily integrate elaborate layouts, appearances, and branding elements that would be difficult or difficult to attain with standard design methods.

Applications Across Industries

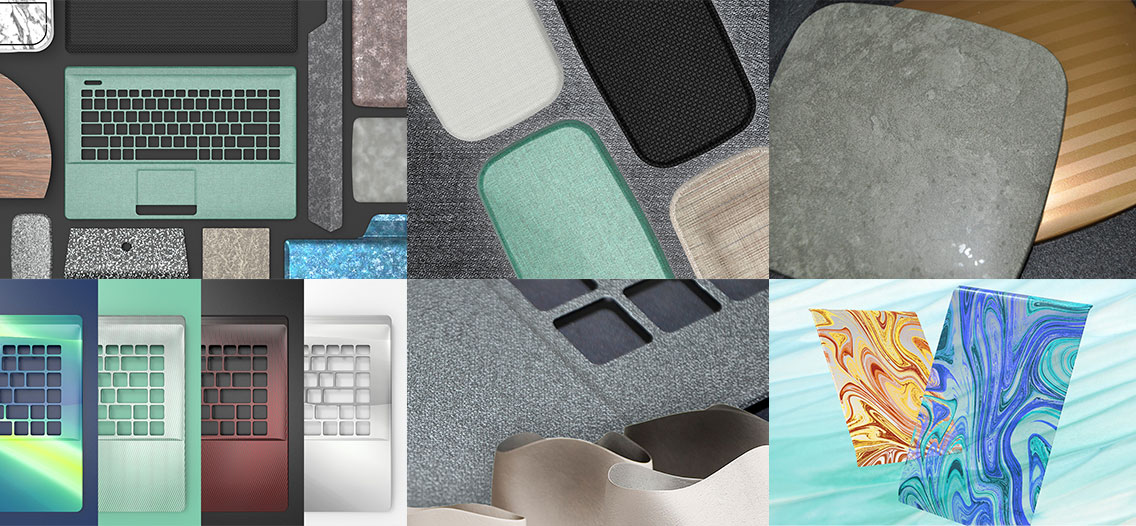

Throughout numerous markets, in-mold decors have actually located functional applications that boost both the visual appeal and sturdiness of items. In the vehicle sector, in-mold decorations are frequently made use of for indoor trim components, such as center consoles and door panels, offering a high-quality coating that is immune to scratches and fading. The customer electronics sector advantages from in-mold decorations on things like smartphone cases and laptop computer covers, where intricate styles can be seamlessly incorporated right into the production procedure. In addition, the appliance industry makes use of in-mold decors to create resilient and trendy control panels and fascia for items like stoves and refrigerators. In the plaything industry, in-mold decors are utilized to include vivid colors and comprehensive graphics to plastic toys, guaranteeing a child-friendly and visually appealing look. Generally, in-mold decorations supply a reliable and affordable method to enhance the aesthetic appeals and longevity of items across a variety of sectors - In-Mold More hints Decorations.

Future Fads in In-Mold Technology

The development of in-mold decors is positioned to continue shaping the landscape of product style and production as Future Trends in In-Mold Technology promise ingenious services to further boost visual appearances and item durability. Additionally, innovations in digital printing methods are allowing makers to achieve greater customization and information in in-mold designs, opening up brand-new possibilities for imaginative product layouts. One more substantial trend is the assimilation of smart modern technologies, such as NFC tags or LED lighting, straight into in-mold decorations, including interactive and useful look at this site aspects to products.

Conclusion

In-mold designs have actually reinvented the production procedure by effortlessly integrating layout aspects right into products. With its many benefits and functional applications across various industries, in-mold modern technology is positioned to proceed forming the future and advancing of production.

By understanding the intricacies of the in-mold procedure, makers can produce visually striking items with durable, durable decors that boost both the looks and functionality of the last product.

Advancing product looks and toughness, in-mold designs use a streamlined approach to integrating attractive aspects during the production process. One of the vital advantages of in-mold designs is the smooth combination of graphics, textures, and shades directly into the product during the molding process.The evolution of in-mold decorations is poised to continue shaping the landscape of product style and production as Future Trends in In-Mold Modern technology promise cutting-edge services to even more enhance aesthetic appearances and item longevity.In-mold designs have actually transformed the manufacturing procedure by effortlessly integrating design aspects into products.